Protton

Online

Training

WHY TO GET TRAINED

To get an answer to this question let us understand ‘Training’ differs from ‘Formal Education’. Most of the times ‘Training’ is a ‘Self Decision’, ‘Self-Motivation’ with a ‘specific goal’ in a ‘specific subject’ & ‘Under the guidance of Specific Trainer’.

A good Trainer

- Can change your ‘Perspective’ to look at the subject

- Brings in his ‘Decades’ of ‘Experience by discussing ‘Real case studies’

- Not only tells you ‘HOW’ but also ‘WHY?’

Now, why to get trained?

A good Training

- Makes your ‘WHY’ clear

- Makes you ‘confident while taking decisions’

- Gives you an ‘Leading Edge’

- Gives a ‘Path for future progress’

Listen before Subscribe

Creating Great Learning Experience

Advanced Pipe Stress Analysis

Most of us know ‘What to do’ in engineering but very few know ‘Why to do it’. To get the answer of ‘Why’; Protton Synergy is announcing a 50 hours courses in Pipe Stress Analysis.

This Course is useful for all engineers who wish to make their basics clear in Pipe stress analysis. If you wish to ‘Experience’ the ‘Stress Concept’ and not only wish to understand it mathematically or in bookish language and the most importantly if you possess patience and passion for the subject then this Course is for you. This Course is divided in 3 nos. of videos. In these Courses we will discuss

the concepts of Displacement Filed, Stress & Strain Field,

Modulus of Elasticity and its significances

what is ‘Tensor’? stress as a Tensor,

Longitudinal stress, Radial stress, circumferential (Hoop) stress

Moment of Inertia,

stress stain curve and practical approach to look towards it.

This Course is continuation of Course-1 and hence applicable for all Mechanical, production engineers irrespective of their experience. This Course is extremely recommended for the under graduates, fresh graduates, piping engineers, engineers working at site and stress engineers. We go little deeper into concepts like

3D state of stress,

Mohr’s circle,

Theories of Failures:

Maximum Shear Stress Theory,

Von mises theory,

Importance of stress analysis.

Also, a simple problem is solved by hand calculations to calculate the stresses in the system. The intention of this Course is to make the participant to look at the problem without taking help of software

A highly recommended Course for all stress and piping engineers.

There are various codes based on their applications. For example, ASME B31.1 is for Power piping, B31.3 is for Process Piping, B31.4 is for Liquid Hydrocarbon transportation etc. It is like ‘learning languages very close to each other’. If you know one language and its grammar well then it is simple to grasp other languages. Unfortunately, most of the Piping engineers do not read the code carefully, some of them ‘Read’ the code but cannot ‘interpret’ it. The equations provided in the codes are followed as it is.

However, all these equations are closely related to basic stress concepts and engineering theories which we learn in schools, universities and if an engineer understands ‘Why’ behind the code equations, are written in a particular way then he/she gets an ability to relate them with new challenging problems. Also, it makes the understanding of code clear.

This Course is continuation of previous Course and hence must be heard after completing Course 3. This talks about

the code equations in detail,

why equations are written in a particular way,

what is the significance of + and – sign?

what is ‘stress range’?

stress relaxation

Self-springing of material

what are liberal stresses

Scope and Exclusions of ASME B31.3,

Primary stresses equation and its allowable,

secondary stresses equation and its allowable

occasional stress equation and its allowable

This Course is continuation of previous Course and hence must be heard after completing Course 3. This talks about

the code equations in detail,

why equations are written in a particular way,

what is the significance of + and – sign?

what is ‘stress range’?

stress relaxation

Self-springing of material

what are liberal stresses

Scope and Exclusions of ASME B31.3,

Primary stresses equation and its allowable,

secondary stresses equation and its allowable

occasional stress equation and its allowable

Defining the load cases is very important in pipe stress analysis as it is a relation between the software and the code requirements. Defining right load cases and understanding the mathematics behind the load cases is very essential. Most of the time it has been observed that engineers do copy the load cases or try to learn them by heart.

This Course talks about

how to write load cases their nomenclature

there are various methods of combination such as scalar algebraic.

Also, it tells about the answers of many critical questions like ‘why a particular load case is written in a particular way’?

how to write the load cases using Caesar II software.

What are the different types of load cases?

How the allowable stresses are understood by the software when you call a particular load case by a particular name.

How to write the load cases when a spring is introduced in the system.

How to write load cases when force present in the system.

This model also relates the load cases with the code equations. This Course is extremely useful to the engineers with experience less than 5 years for those who wish to understand the mathematics and ‘Why’ behind the load cases.

Today’s world is software driven. Engineers are no exception to it. It has been observed that engineers cannot give the solution without having software with them. Then it becomes essential to know the advantages and the limitations of the tool we are using. Hence knowing the stress analysis software and its advantages / limitations, the way it has been programmed etc. is very important. CAESAR II is one of the finest stress analysis software using beam element.

In this Course we will learn

-

basic elements

-

hand calculation of thermal force and stresses. Evaluating them with scissor to answer

-

how software works.

-

important features of configuration setup.

-

what is ‘degree of freedom’

-

introduction to modelling commands.

-

Node and connecting Node, its application.

-

how to apply wind and earthquake loads.

-

advantages and limitations of the software.

-

difference in in pipe element and rigid element.

Course number 7 is continuation of Course number 5. In Course number 5 we had learnt the theory about the load cases, How to write them, it’s combination methods.

In this Course we are going to learn

how to build the load cases in CAESAR II software.

What are the different features of this wizard?

How to make the most out of the various advantages provided by the software.

How to apply wind, earthquake, forces in the load cases.

How to interpret the results.

How to correlate the results with the code.

How to identify whether liberal stress is on or not.

How to interpret the positive and negative sign convention in CAESAR II.

How to backtrack the sources of forces and stresses by integrating the results.

After completing Course number no. 1 to 7 successfully now we have reached to a stage where we should start doing experiments. For a stress engineer it is the most essential to keep on trying, doing experiments, make changes into his /her model and look at the results. At the initial stage this ‘trial and error’ method is very effective to learn the stress analysis. At this stage engineer should start predicting the results of small model and verify it with CAESAR II software. The answers what we get teaches us a lot. This Course has been designed keeping in mind that the listener is new to the software.

In this model we will learn

study the effects of temperature, supports and layout on the results,

how to reduce the forces and moments,

basic techniques how to solve a stress system, comparing the results.

Learn few handy commands like Copy, duplicate and rotate

liberal stress and its effect on allowable stress

Our trainer strongly believes that when any stress analysis problem comes in front, the solution of that problem should get first formed in your mind. Then one should model it accurately into the software and then look at the results. If the results are as per your predictions then you are on the right track and if not then you can correct your understanding by looking at the results given by the software. In this journey it is very important to know how our ancestors or the previous generation of the engineers used to perform the analysis when they did not have such a sophisticated software.

In this Course we are going to learn a method called “Guided cantilever method”. This method was the basis to determine the minimum required flexibility into the piping system when we had no software. Based on this method number of graph, charts were developed. In this Course we will understand the theory of guided cantilever method, we will solve a problem using hand calculations based on this method and then we will verify the same problem using Caesar II software. We will look into the results and try to compare it with the hand calculation and we will try to learn the accuracy of this method and its limitations as well.

Front End Engineering and Design (FEED) stage or initial stage of detailed piping design, one of the initial deliverable to the site for construction is ‘pipe rack design’. Even it is required to calculate the bulk material take off (MTO). Hence a piping engineer or a stress engineer is always asked to provide ‘the number of expansion loops’ which would be needed for adequate flexibility of the pipes running onto the pipe racks. At this stage we do not have piping isometric or General Arrangement drawings or 3D model. Hence modelling pipe rack piping in the stress analysis software is sometime difficult.

In this Course we will learn

to predict the number of loops on a line,

calculated the forces and moments on the anchor base using graphical methods and evaluated them using software results

what should be the distance between the two anchor points on the pipe rack,

what should be the height of the loop.

what about the sizing a 3D loop (three-dimensional loop)?

We can refer to this Course wherein we have solved an expansion loop sizing problem using nomograph and then we have also demonstrated its validity, limitations, advantages of the graphical method against using an expansion loop sizing Wizard provided in CAESAR II software. This Course is extremely useful for Piping design engineers, Piping designers, Project managers and of course for stress engineers.

The final outcome of the extensive stress analysis is nothing but ‘IFC isometric’ which means ‘Issued for construction’ isometrics. In these isometrics we get a final pipe route and type of supports which have been approved and recommended by the stress engineer. Here all the wisdom, knowledge and experience of a stress engineer gets converted into the selection of right type of supports.

There are various kinds of supports such as rest supports, guide supports, limits stops, springs, snubbers, Struts. Each support has got its own unique features. Hence understanding the language of stress analysis software and then converting them into a appropriate support is very essential.

In this Course we are going to learn

different types of supports, their applications,

where to use which type of support.

Do’s and don’ts about support.

How to read arrow marking on stress iso and converting it in physical supports

Simple supports and few complicated supports

primary supports and secondary supports.

This Course is useful for piping engineers, designers, stress engineers, mechanical contractors at site and civil engineers.

Few piping Engineers and stress engineers do think that the springs are provided in the piping system to absorb the expansion of the pipe. However, this is not the complete truth. The use of spring hanger is mainly to take the dead weight of the Pipe and to allow if free expansion. Most of the times engineers, by experience, do know where and when to use the spring support. But they cannot select the string without the help of the software. Also, they struggle to select this spring from the vendor catalogue. Further they find it difficult to give a decision whether we can use a spare spring which is available in the stock /inventory at a particular place. To give these decisions the concept of variable spring, hot load, cold must be clear in mind.

In this Course we will learn

what is Hot load

what is Cold load

what is Variability of the spring

How they are co-related

What is cold load setting

what is hot load setting

what is extended load range

How to read Spring catalogue

How to select spring from catalogue

various entries of spring Wizard in detail

How to write the ‘Load cases’ with spring.

Also, we will perform hand calculations and will verify them using Caesar II software.

When it comes to ‘Constant efforts spring’, most of the engineers step aback. There is a kind of ‘suspense’ in the design and usage of constant effort spring due to lack of information. In this Course we will attempt to learn

how constant effort spring works

understand its internal mechanism in a simple way

the mathematics involved in it.

learn to read vendor catalogue

how to select a constant of a spring through it

how to write the load cases

will perform the a practical and verify our theory against the results obtained.

Most of the piping engineers and stress engineer work in downstream Oil & Gas industry or in refinery piping. But in hydrocarbon service the usage of expansion bellow is prohibited. Due to this reason most of the stress engineers do not get exposure to work with Expansion joints or bellows. This makes it a grey area for them. There are various kinds of bellows such as fabric bellows, rubber bellows, metallic bellows. Each type of bellow has its own advantages and disadvantages. Further in each type, for example in metallic bellows, there are sub types such as Tied bellow, untied bellow, pressure balanced bellow etc.

In this Course we will be learning

the different types of Expansion joints

Pressure thrust due to bellow

How to eliminate it.

Tied bellow, untied bellow, pressure balance bellow

expansion joint wizard in CAESAR II

how to read the catalogue of expansion joint

how to select the below

how to model a pressure balance below

This Course is useful for piping engineers, engineers at site and stress engineers who wish to learn the Expansion joints.

Stress Intensification Factor also known as SIF is a topic of research and probably the least understood subject in Pipe Stress Analysis. We do not claim to be master of this subject. But definitely would like share the information we have in this domain. In this Course we will learn

what is flexibility factor

What is SIF

How to calculate it using appendix D of ASME B31.3

The limitations of ASME B31.3 appendix D

Markl’s work in SIF

An overview of Finite Analysis method to get SIF

The myths and truths about SIF

How SIF is used in stress equations

Should we consider SIF in Sustained and occasional cases?

Mitre bends and its SIF

How flexibility of the bend changes with its connection to flanges.

Discussing technical paper authored by the faculty

Flange leakage is one of the critical safety aspects. Even though it is practically impossible to give guarantee that flange would not leak (as it depends on various other factors as well), there are industry approved practices to ensure Flange Leak would not happen. In this Course we will learn

Pressure equivalent method and manual calculations

NC 3658 method manual calculations

Verifying CAESAR II results against hand calculations

Understanding the basics of why flange leak

ASME Section VIII method input in CAESAR II

ASME section VIII method manual calculations

Reference documents from flange leakage analysis

Supporting to avoid Flange leakage

After completing all these Courses now we have come to the stage to understand how the work flow is in real life. How engineers in consultancies work. This Course though looks simple but extremely important for junior engineers who would become an asset to the company if understood the work flow from day one.

In this Course we will learn

How to identify stress critical lines

How to make critical line list

Documents needed to form a system

How to form a Stress System

Where to break the systems

What to read in reference documents?

how to extract report from CAESAR II

How to prepare stress isometrics

How to select and call support from support standard

How to write a good stress report

If you are an engineer representing client or PMC (project management consultant) or a lead stress engineer and your job description demands to check the stress calculation / report then this Course is for you. In fact, slowly all the stress engineers have to reach to this phase. Initially he /she has to self-check his/her own system and slowly start checking stress calculations prepared by others. Unfortunately, the checking time of the stress system is rarely given justice in the man hour estimation despite the fact that the ‘Checker’ is ‘responsible’ for the quality. In such situation checking becomes ‘an art’.

In this Course we will learn

Minimum or common check points in CAESAR II model

Critical check points

How to check the results by applying ‘Thumb Rules’

How to identify if the analyst has ‘cheated or managed the results’

How to check hard copy report

Common errors

Many times, at the initial stage of the project when the stress analysis has not started yet you may have to provide the loads (Forces / Moments) to civil engineer to design pipe rack or a platform. This activity is also applicable to Non-stress critical lines. Sometimes piping engineer (who may not be a stress engineer) has to provide these loading without using a software. Hence this Course is extremely useful to piping engineers, piping designers and off course stress engineers.

In this Course we will learn

How to give UDL (Uniformly distributed loads)

How and when to provide Point loads

How to calculate minimum axial loads on anchor bay

Thumb rules of loading

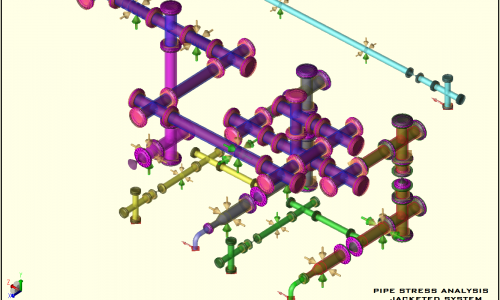

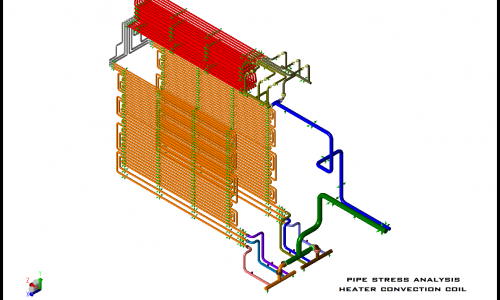

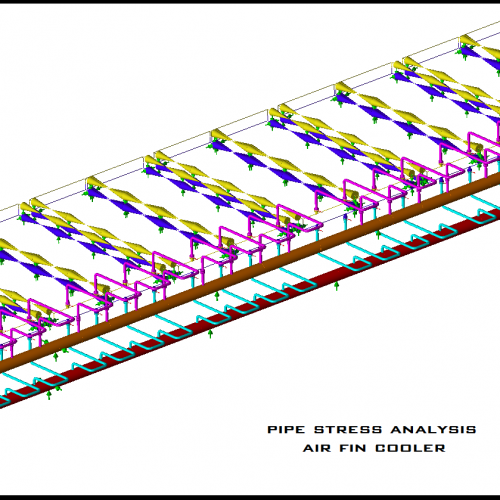

Now we have come to an end of this Course. This is right time to review few critical systems. The participant must understand that it takes nearly 30 to 40 hours to complete one critical system (with 5 to 6 stress critical lines in it) in all aspects. So practically it is not possible to model each and every system in limited time. However, we can review the ready models of such a critical system and the comments on those. Each of these systems have typical behaviour, typical piping route requirements, typical supporting and hence learning it by experts adds in your knowledge.

In this Course we will have overview of

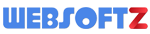

Tank Piping

Heat Exchanger Piping

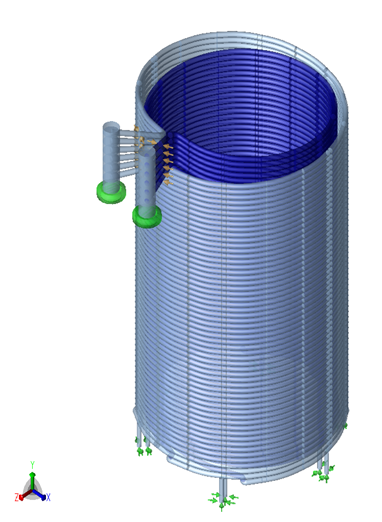

Column Piping

Air Fin Cooler Piping

Turbine and Compressor Piping

BE PATIENT WHILE LEARNING

Today we need everything ‘FAST’, but this is not applicable to Training. Give ‘Dedicated time’ to get the most out of it. Attend lectures with ‘Pen & Pad ready’.

LEARN AT YOUR OWN PACE

USE FORUM FOR CONTINUOUS LEARNING

During and after the training continue reading and writing in Forum. Keep learning from peers, trainers and experience the knowledge sharing.

CHALLENGE YOUR LIMITS

Take a challenge to complete the course in ‘specific time’, take exams seriously, ask doubts, read all references, challenge your limits.

MEET YOUR TUTOR

Mr. Gaurav Bhende

(M. Tech. Chartered Engineer)

The faculty is Founder and Director of Protton Synergy PVT. LTD. He has more than 19 year of experience in Pipe Stress Analysis and conducted several Professional Training Courses on Stress Analysis using CAESAR II software in numerous international engineering companies and Institutes as a freelance Trainer since 2009. Gaurav Bhende has won the First Prize in a Global competition called “Driver of Success” where case your excellence in CAESAR II usage in Pipe Stress Analysis is to be demonstrated.

Gaurav has been invited to participate as a ‘Guest Speaker’ in International conferences held in USA, India and UAE. Gaurav Bhende has presented numerous White papers on various topics of Pipe Stress Analysis like Buried Pipe Analysis, Seismic Analysis, stress Intensification Factors, surge analysis in International Journals and Conferences including ASME conference. The forthcoming papers on Computational Fluid Dynamics, Vibration mitigation and few more topics.

He is known for his specialty injecting his subject into the Blood of the student and making the student ‘feel excited’ as he understands the ‘Why’ behind the concepts.

Be Updated with the latest Industry Trends

Do you want to become a Technically Sound Pipe Stress engineer?

Gaurav Bhende M Tech, Chartered Engg. Who should read: Mechanical engineers, Piping / pipeline...

WHAT IS A SURGE PHENOMENON?

Gaurav Bhende M Tech, Chartered Engg. Just imagine thousands of people running a marathon race...

Difficult Interactions in corporate world

Prachee MahambareNLP Practitioner and Soft skills Coach. PROFEX9766 316 735/ 9764 669...