Description

Would you be interested knowing the answers of questions like:

‘What does exactly ‘Stress’ mean: A scalar or vector or more?’

‘What exactly should I read from ASME B31.3 code and other standards like API 610, API 650 etc.?’

‘Why the spring is provided in piping and how to select it’

‘Why Flange leaks, nozzle cracks, line deforms, pipe to pipe fitting cracks and how to calculate it?’

‘How CAESAR II calculates the stresses? How to read stress report?

‘How stress analysis used to be performed in early stage when there were no computers’

……… And answers to many more ADVANCED questions along with Practical problems.

To enhance our mechanical design engineers’ skills in analysing, studying, and solving different engineering problems.

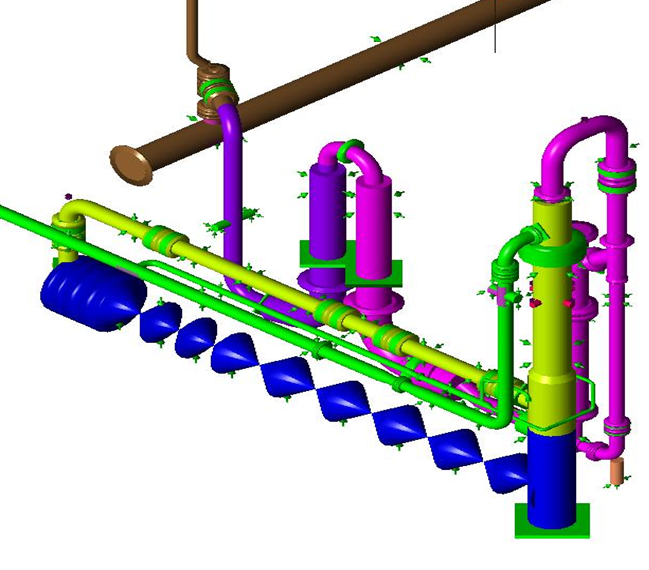

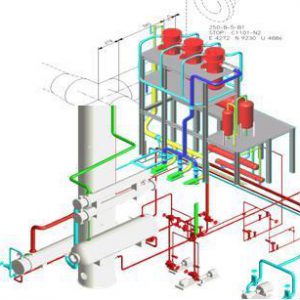

The course starts with the fundamentals required to perform Pipe Stress Analysis. It also talks about the International code requirements, best industry practices and then ends with Practical application of Pipe Stress Analysis using “CEASAR II” software to build piping system models and to analyse the output.

The piping Engineer with knowledge of “Pipe Stress Analysis” can work in all core engineering industries (viz. Refineries, Oil and Gas, Petroleum sector). He / She will able to deliver independently in areas of Piping Design, Layout and Analysis.

WHO SHOULD ATTEND?

Quality Assurance Staff, Piping Design engineers, stress engineers, designers

Any aspiring engineer, he/she can be a trainee engineer, designer, Sr. Engineer, Plant Operating engineer, Project engineer or a Manager, who wants to clear his/her fundamentals clear and wants to know more about this subject and software can attend this course

Syllabus:

- Important concepts of Stress Analysis.

- Theories of Failure: Maximum Shear stress Theory, Von Mises Theory.

- Interpreting International Piping code equations, ASME B31.1, B31.3

- Theory behind load case formation and CAESAR II practical on it.

- Understanding CAESAR II software, its configuration set up, miscellaneous modelling commands.

- How to read and interpret results of CAESAR II output, their sign convention and tracing back the cause of forces / stresses.

- Support types and their application. Special supports like snubbers, struts, sway Braces and CAESAR II practical on it.

- Manual Spring Selection and theory behind it and CAESAR II demonstration.

- Constant Effort Spring working

- Pipe Span Calculation

- Guided Cantilever Method, Nomograph, Thumb Rules for flexibility and its verification using CAESAR II.

- Expansion Loop sizing by Graphical method and its verification using CAESAR II wizard.

- Criteria to identify stress critical lines and system formation.

- Expansion Bellows, Thrust force, application of Bellows, which type of bellow to be used at what location and how to model bellow in CAESAR II.

- Slug force, PSV Thrust force, Rupture Disk force calculations and supporting against it. Corresponding CAESAR II practical.

- Stress Intensification factor, Flexibility factor.

- Flange leakage analysis calculations

- Calculation of stresses in shell with attachment using WRC107

- WRC297 flexibilities

- Overview of Typical systems such as Piping connected to Tanks, Pumps, Exchangers, Columns, Air Fin coolers, turbines.

- At the end of the course live interaction with faculty through Video conferencing.

Reviews

There are no reviews yet.