Description

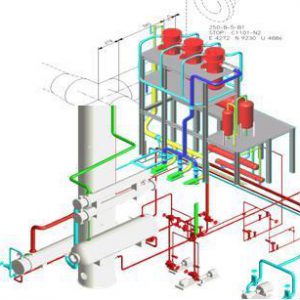

- Theory:

- Introduction to Pipeline Stress Analysis and Role of Stress Engineer.

- Basic Stress concepts applicable in Stress Analysis.

- Theories of Failure

- Interpreting International Piping code equations, ASME B31.4, B31.8, AS-2885.

- Theory behind load case formation.

- Support types and their application.

- Anchor block calculations and overview of its FEA calculation.

- Pipe Span Calculation

- Piping flexibility and Stress Intensification factor

- Flange leakage analysis calculations

- Protechtion against Soil Liquefaction: PGD and Buoyancy

- Pipe buckling,

- Pipeline Thickness calculations, Bend radius calculations.

- Detail discussion of Buried Pipe behavior.

- To understand significance of various soil properties like density, cohesive pressure,

friction angle etc.

- Comparing various methods of analyzing buried pipe including American Lifeline Alliance Method.

- Reading of alignmnet sheets

- Reading of Station approach drawing.

- Launcher /Reciever / Monolithic Insulation drawing checking

- Unrestrained and Restrained pipeline concepts

- Unrestrained length calculations.

- Pipeline checklist

- Practical:

A case study covering follwing aspects.

- Introduction to CAESAR II software and its Configuration file etc.

- Quick and effective techniques to model Buried pipe.

- Buried Pipe analysis using Peng’s Method.

- Buried Pipe Analysis using American Lifeline Alliance Method.

- Buried Pipe analysis using manually calculated soil stiffness.

- Load case formation

- Mark up on Alignment sheets

- Report formation

Reviews

There are no reviews yet.