OIL AND GAS INDUSTRY

Case 1

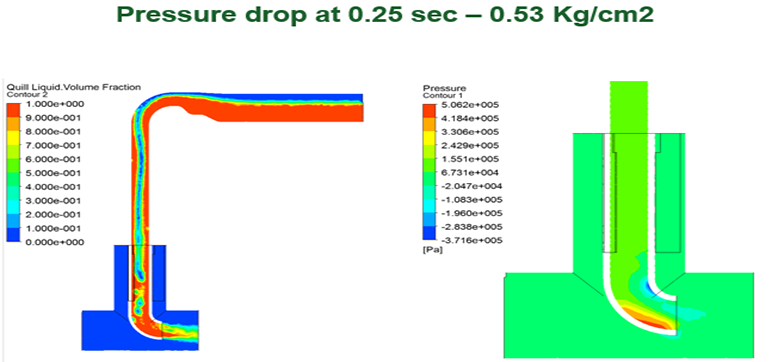

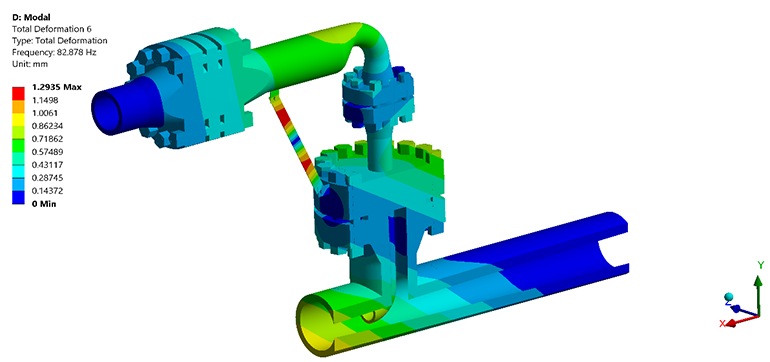

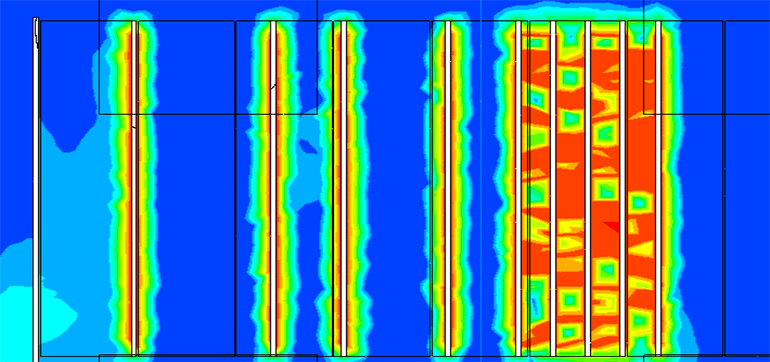

Injection Nozzle - fluid induced vibrations due to multiphase flow, high pressure and high velocity, structural integrity & thermal shock analysis. An injection nozzle was introduced in the system to reduce the temperature of the working fluid. Four different fluid mediums were considered for computational fluid dynamics. Multiphase analysis with volume of fluid model was considered for the analysis. The CFD results were mapped on the FEA solver. Imported CFD results, forces and moments were considered for the mechanical static analysis. Natural frequency of the system is analyzed and behavior of components under lower frequency is studied. Expansion of quill and effects of differential temperature is studied.

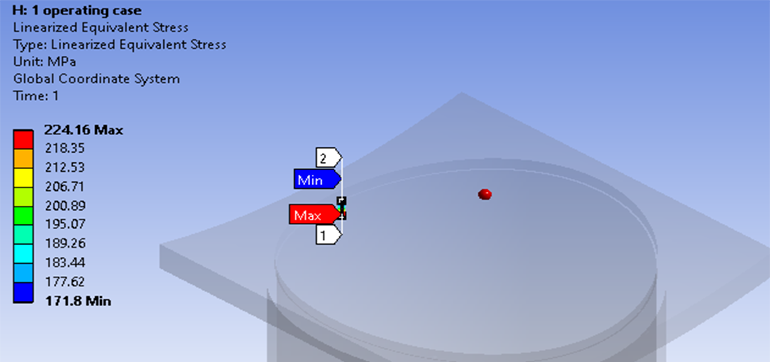

Case 2

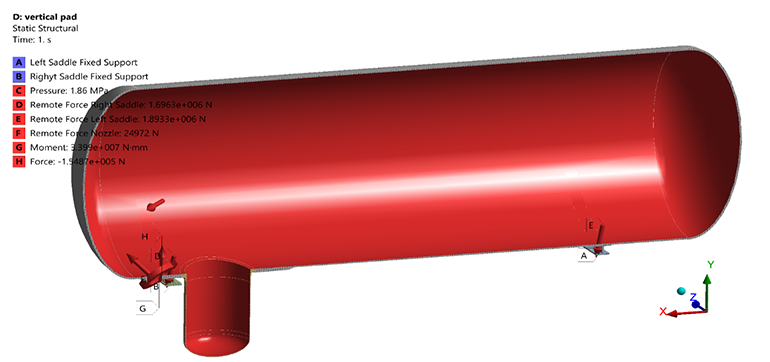

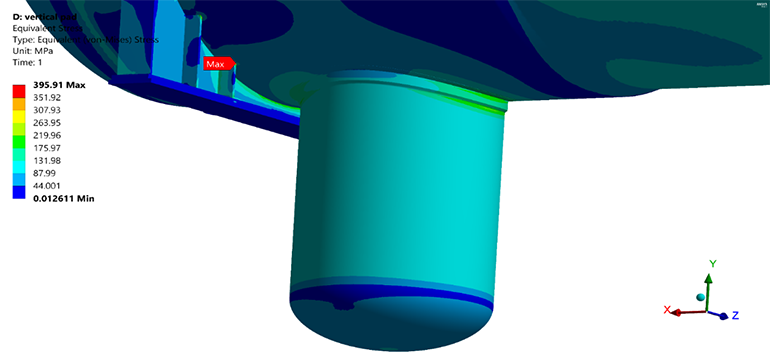

Finite element analysis of pressure vessel. The scope of the case study is to analyze the junction near the boot and shell and validate the stresses induced due to change in position of saddle

DEFENCE INDUSTRY

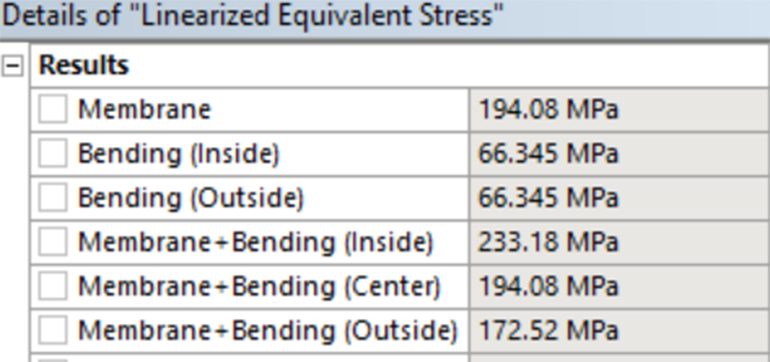

Case 1

To analyze the behavior of the component under lower and higher frequencies. The following system is a control unit used in defence applications. Different vibrations are induced in the system due to motion of the parent vessel or due to external loading.

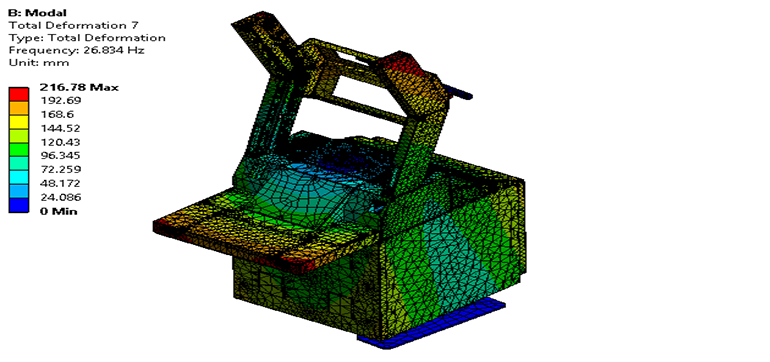

Case 2

To study effects of conduction, convection and radiation in power supply units. The domain has eight fans placed at various locations. The problem statement was to analyze the flow pattern of air and check for hot spots within the domain.

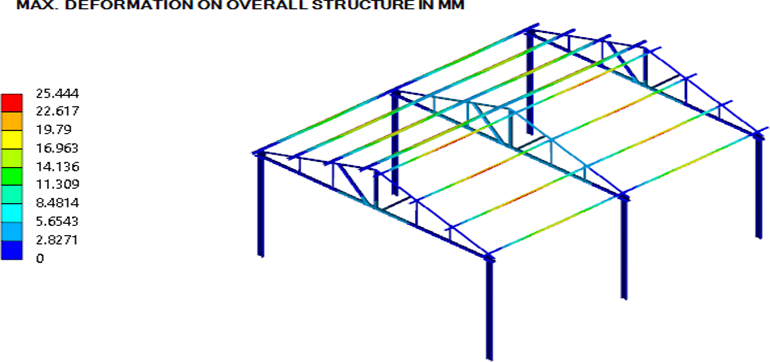

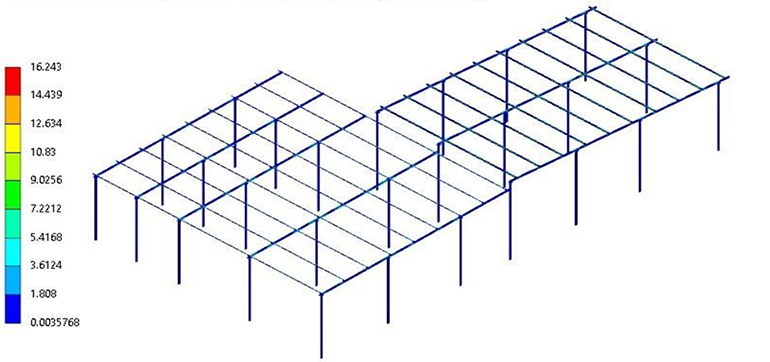

REGULAR AND IRREGULAR STRUCTURES

Analysis of regular and irregular structures to study the contact behavior of members during wind and seismic loading.

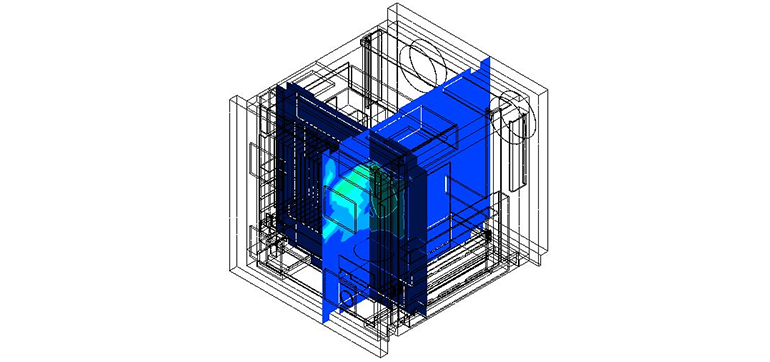

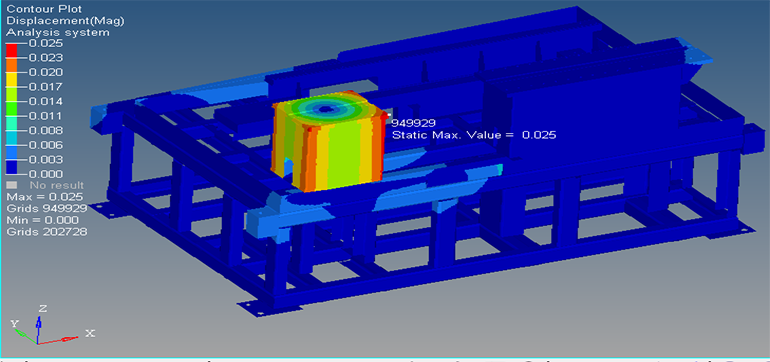

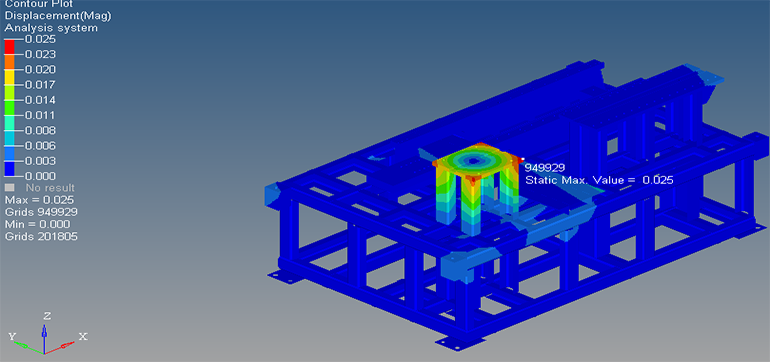

SPECIAL PURPOSE MACHINING

Case 1

To reduce the weight of the module without affecting its load bearing capacity. The image at the bottom shows the material removed from the component thereby reducing the weight of the component. The percentage change of the stress and deflection values for the revised case is very less. Thus, the revised case was implemented.

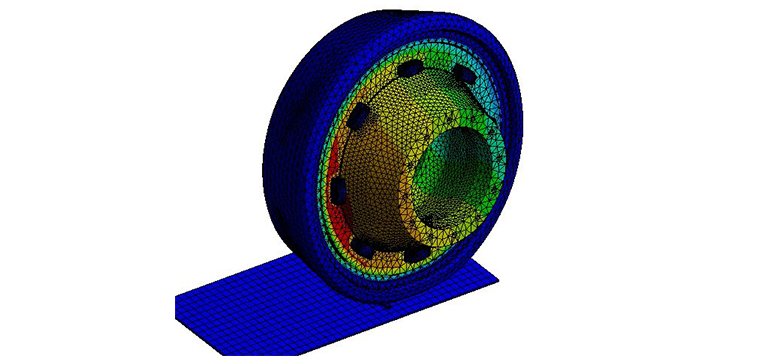

Case 2

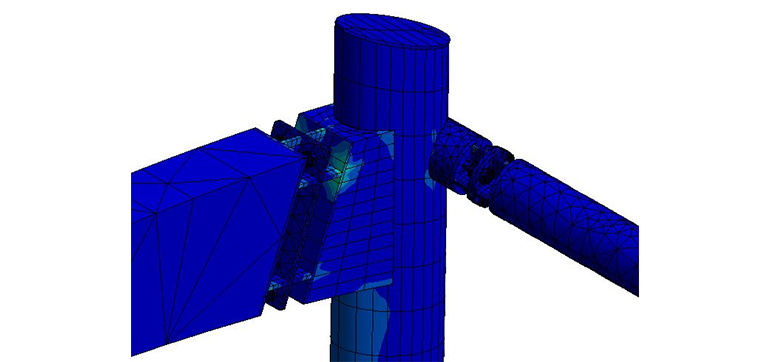

The image depicts explicit dynamic analysis of 1.5 m diameter coal crusher wheel. Different materials such as brass, copper, steel and rubber as used in this wheel are to serve the coal crushing purpose. The scope of this project was to calculate the pressure at the contact surface and to determine the brazing strength.

EXPLICIT DYNAMIC ANALYSIS OF COAL CRUSHER WHEEL